Welcome back to the Diamonds Hatton Garden blog where we bring you the latest insights from our Hatton Garden Jewellers. A gift from nature, diamonds are one of the most precious and valuable gemstones in the world, prized for their brilliance, durability, and rarity. Cherished for what they represent and the promises they symbolise, diamonds have been used in jewellery and as symbols of wealth, love and devotion. However, before they can be set into a piece of jewellery, they must first be cut and polished from the rough form in which they are found. The process of cutting a diamond from the rough is a highly specialised and skilled process that requires a combination of artistry, precision, and technology. In today’s blog, we will explore the various steps involved in the diamond cutting process and the techniques used to transform a rough diamond into a beautiful gemstone.

Historically, diamonds were cut using primitive tools such as point tools and sandpaper. Point tools were used to create grooves on the diamond’s surface, which were then used to guide the placement of sandpaper. The diamond was then rotated against the sandpaper to wear away the rough edges and create facets. This process was time-consuming and imprecise, and often resulted in significant diamond loss.

In the early 1400s, diamond cutting in Europe was revolutionised with the invention of the diamond cutting wheel. This tool, powered by a foot pedal, allowed for greater precision and consistency in diamond cutting. However, it still required significant skill and experience to use effectively.

In the 1700s and 1800s, diamond cutting was further improved with the introduction of new cutting techniques and tools, including the rose cut and the table cut. These new cuts allowed for more efficient use of the diamond and created a greater range of diamond shapes.

Today, diamond cutting is a highly advanced and technical process that uses computer-aided design (CAD) software and advanced cutting tools to create diamonds with exceptional precision, symmetry, and brilliance.

The first step in the diamond cutting process is planning. This involves studying the rough diamond to determine the best way to cut it to maximise its beauty and value. Diamond cutters use specialised software to analyse the rough diamond’s shape, size, and inclusions to determine the optimal cut that will yield the highest quality diamond.

Technology has had a significant impact on the diamond cutting industry, and it has greatly aided diamond cutters in many ways.

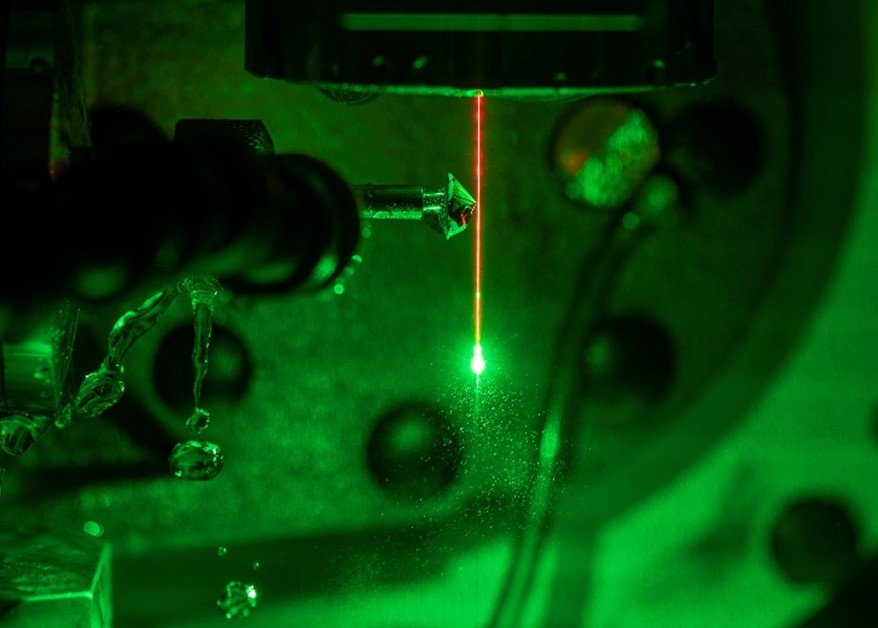

Precision cutting: Technology has enabled diamond cutters to create more precise cuts, shapes, and facets. Laser cutting and polishing machines, for example, can produce exacting cuts with greater accuracy than traditional cutting methods. This precision ensures that diamonds are cut to the ideal proportions to maximise their brilliance, fire, and scintillation.

Enhanced analysis: Technology has also enabled diamond cutters to analyse diamonds in greater detail. For example, advanced imaging techniques can be used to analyse a diamond’s inclusions, internal and external characteristics, and its overall structure. This information can help diamond cutters to make more informed decisions about the cutting process, ensuring that the diamond is cut in a way that maximises its beauty and value.

Improved efficiency: Technology has made the diamond cutting process more efficient. Computer-aided design (CAD) software, for example, can be used to create 3D models of a diamond, allowing cutters to experiment with different shapes and cutting styles before they make the first cut. This saves time and reduces waste, making the process more efficient and cost-effective.

Cleaving or Sawing

Once the diamond has been analysed and planned, the next step is to cut the rough into smaller pieces. This is typically done by either cleaving or sawing the diamond. Cleaving involves using a specialised tool called a cleaver to split the diamond along its natural cleavage planes, which are areas of weakness in the crystal structure. Sawing, on the other hand, involves using a diamond-tipped saw to cut through the diamond along a predetermined line.

Bruting

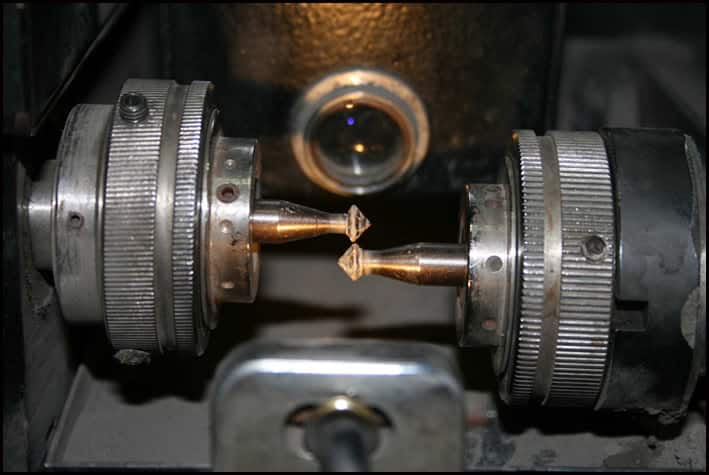

After the diamond has been cleaved or sawn, the next step is bruting. This involves rounding out the diamond’s edges to prepare it for the faceting process. Bruting is typically done using a spinning wheel that grinds the diamond against a second diamond or metal plate, gradually shaping it into a round or oval shape.

Blocking

Once the diamond has been rounded, the next step is blocking. This involves shaping the diamond into a more precise form, such as a square or rectangle. Blocking is typically done using a process called marking, where the diamond is marked with a special pen to indicate where it should be cut.

Faceting

The most critical step in the diamond cutting process is faceting. This involves cutting and polishing the diamond’s facets to create the final gemstone’s shape and brilliance. Faceting is typically done using a specialised machine called a faceting machine, which uses a series of diamond-tipped wheels to grind and polish the diamond’s facets.

There are several different types of cuts that can be used to create a diamond’s facets, each with its unique set of characteristics and beauty. The most common types of cuts include:

- Round Brilliant Cut: The round brilliant cut is the most popular diamond cut, featuring a total of 58 facets that maximise the diamond’s brilliance and fire.

- Princess Cut: The princess cut is a square or rectangular cut that features a brilliant and fiery sparkle.

- Emerald Cut: The emerald cut is a rectangular or square cut that features long, narrow facets that create a classic and elegant look.

- Cushion Cut: The cushion cut is a square or rectangular cut with rounded corners that features large facets that maximise the diamond’s brilliance.

- Oval Cut: The oval cut is an elongated cut that features a brilliant and fiery sparkle.

Final Polishing

After the diamond has been faceted, the final step is polishing. This involves using a specialised polishing wheel to remove any remaining scratches or imperfections from the diamond’s surface, resulting in a final, high-polish finish.

For over 40 years, our family-run team has helped generations of clients across the world to find their perfect item of diamond jewellery. Explore our selection of fancy coloured diamonds for sale as well as our beautiful range of diamond engagement rings Contact our team via harel@diamondshg.co.uk or call +44 7951 060238 for more information and to arrange your appointment. Alternatively, discover our selection of large diamonds for sale, or contact our team to sell diamonds in London.